Logo for download

Contact

Phone: (+420) 730 521 321

Email: info@ce.industries

they wrote about us

06/03/25

Strnad's CE Industries earned 785 million the year before last, Croatian wagons played the main role

06/03/25

Strnad's CE Industries earned 785 million the year before last, Croatian wagons played the main role

24/01/25

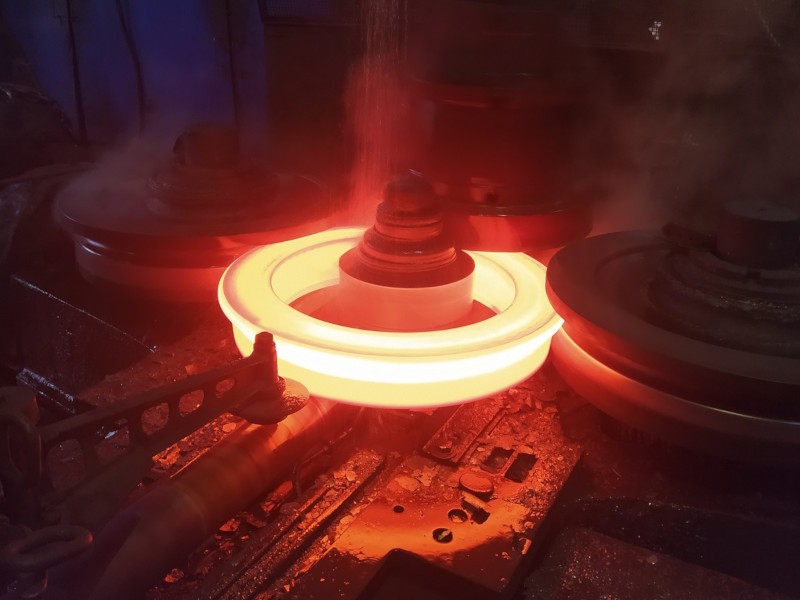

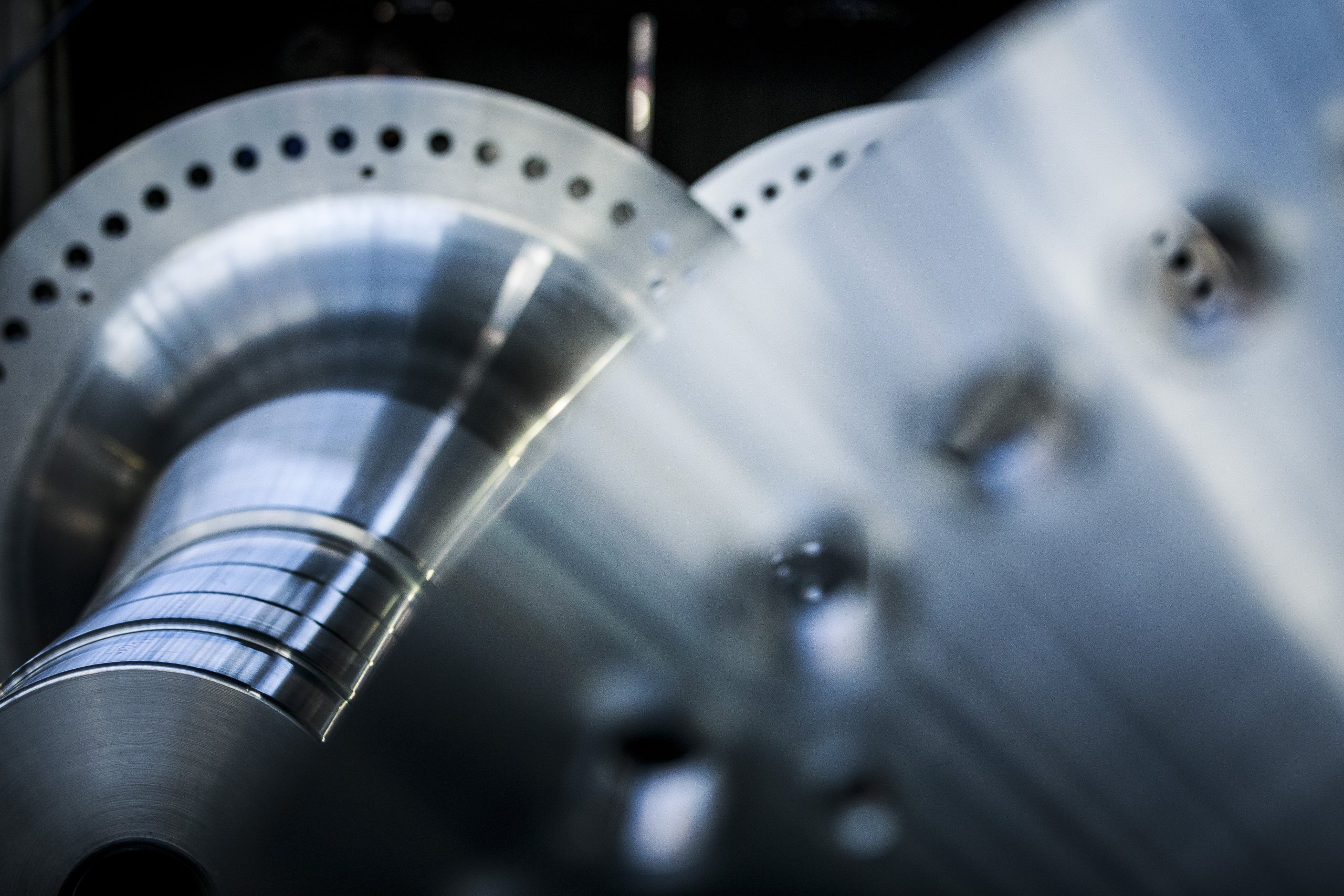

Another production plant started in Liberty in Ostrava, a rolling mill for flat products was launched

24/01/25

Another production plant started in Liberty in Ostrava, a rolling mill for flat products was launched

23/12/24

Croatian Đuro Đaković is doing well under the Czech Republic. We are heading towards the production of 1,000 wagons per year, says director Maroušek

23/12/24

Croatian Đuro Đaković is doing well under the Czech Republic. We are heading towards the production of 1,000 wagons per year, says director Maroušek

11/11/24

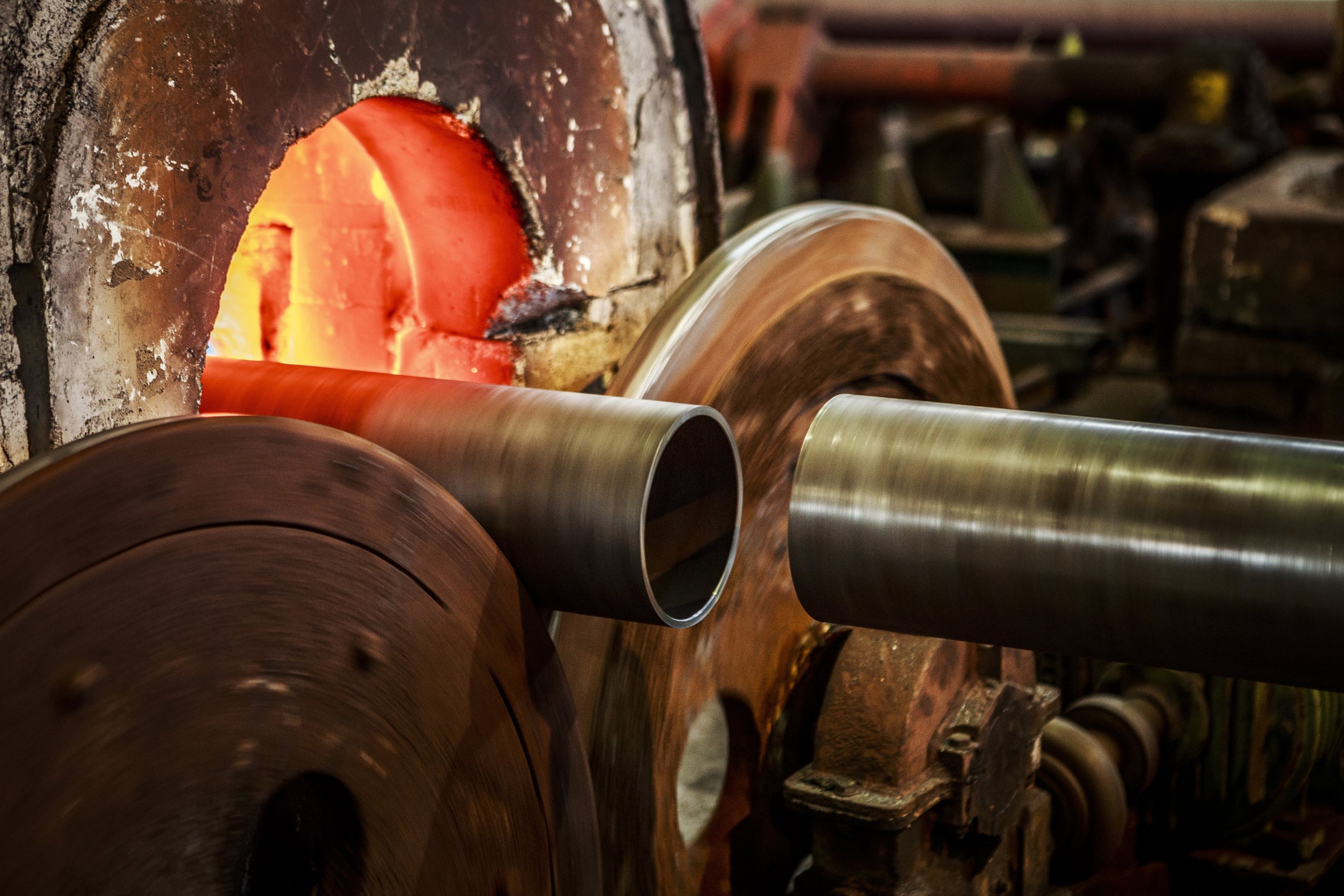

Liberty Ostrava resumed operation of the pipes plant. Hundreds more people are now working.

11/11/24

Liberty Ostrava resumed operation of the pipes plant. Hundreds more people are now working.

18/10/24

We are finally back, some Liberty Ostrava employees rejoice. The plant resumes production of welding rods.

18/10/24

We are finally back, some Liberty Ostrava employees rejoice. The plant resumes production of welding rods.

03/09/24

Financial boost for Liberty. Operation of part of the production will be provided by Jaroslav Strnad's company

03/09/24

Financial boost for Liberty. Operation of part of the production will be provided by Jaroslav Strnad's company

21/08/24

Strnad will modernize retired Black Hawk helicopters. He's bought a company with American soldiers

21/08/24

Strnad will modernize retired Black Hawk helicopters. He's bought a company with American soldiers

07/08/24

MICo and Chemcomex will participate in the supplies for the new construction of the Dukovany blocks

07/08/24

MICo and Chemcomex will participate in the supplies for the new construction of the Dukovany blocks

26/02/24

Strnad sold the energy company Advance Energo to Veolia. He continues to believe in the energy sector, but will bet mainly on nuclear

26/02/24

Strnad sold the energy company Advance Energo to Veolia. He continues to believe in the energy sector, but will bet mainly on nuclear

10/10/23

We want to be the European number three in the production of freight wagons, says the head of Strnad's CE Industries Group

10/10/23

We want to be the European number three in the production of freight wagons, says the head of Strnad's CE Industries Group

29/12/22

It's not about energy prices, but about differences across Europe, says head of Strnad's CE Industries group

29/12/22

It's not about energy prices, but about differences across Europe, says head of Strnad's CE Industries group

01/09/22

Tatra rescuers buy Croatia's largest engineering plant. Strnad and Matera will produce freight wagons there

01/09/22

Tatra rescuers buy Croatia's largest engineering plant. Strnad and Matera will produce freight wagons there

27/06/22

Vítkovické železniční opravny shops increased their sales last year, but their profit dropped slightly

27/06/22

Vítkovické železniční opravny shops increased their sales last year, but their profit dropped slightly

14/05/20

The government wants to pass on the possible increase in electricity prices due to nuclear power to consumers. There should be a new item in the invoices

14/05/20

The government wants to pass on the possible increase in electricity prices due to nuclear power to consumers. There should be a new item in the invoices

12/05/20

ČEZ continues to shut down coal despite covid impacts, this year it will shut down Prunéřov I

12/05/20

ČEZ continues to shut down coal despite covid impacts, this year it will shut down Prunéřov I